|

Product |

|

|

|

|

Product information |

|

| Basic information

: |

| Name: |

HF CGP |

| Model: |

|

| Feature: |

The CGP Series is a new family of inks with outstanding printability and excellent adhesion to PC, PPMA , and processed PET materials.

Developed with environment in mind, this series boated low level of Chlorine( under 900ppm) and Bromine(under 900ppm), with total halogen content under 1500ppm.

|

|

|

| Description: |

|

Ink type : Polyester based air-drying ink.

Usage : Processing and printing of general processed polyester film, PC,PMMA, etc.

Feature : semi-gloss finish with excellent leveling.

Coverage : 30 ㎡ per kilogram using a 250 mesh screen.

Drying time: Sets to touch-dry in 20 minutes at 20℃.

Drying may be slowed down in environments with poor ventilation and large amounts of solvent fumes

When inadequately dried, residual solvent on substrate may cause a loss in adhesion.

For optimal results, cure for 5-10 minutes at 50-60℃

Adhesion: Demonstrates good adhesion, but adhesion varies according to surface properties of the substrate.

Product demonstrate good multi-layer printing compatibility.

Diluents: Standard solvent:T-945

Slow dry solvent : T-947, T-980

Wash-up : T-31

Notes : HF CGP-850 is a half-tone medium, and can be added to inks as a thickener

To improve adhesion, add 5-10% D-Hardener.

As environment awareness generally improves, industrial halogen –free standards have been

established to reduce the damages caused by carcinogens including Dioxin, Cl no more than

900ppm, Br no more than 900ppm, and total halogen content no more than 1500ppm.

A series of Halogen-free inks has been developed in response to said environment demands

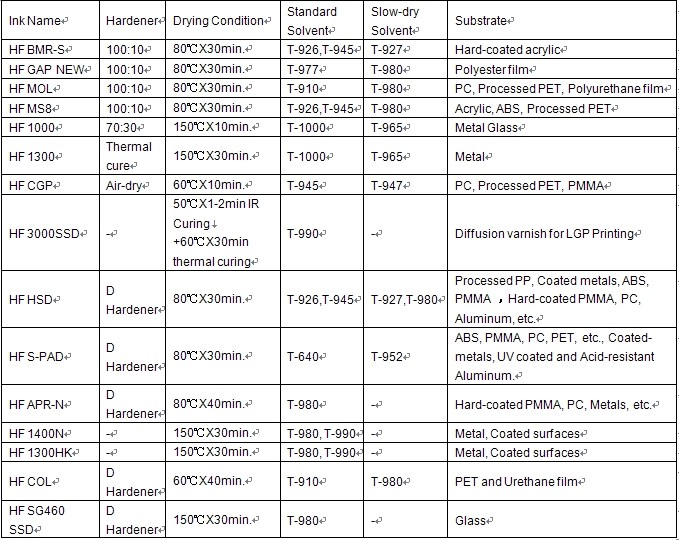

Ink Types and Usage.

|

|

|

|

|