Ink type : Polyester-based two-part reaction type or one-pack thermal curing inks

Usage : Viable for printing on plastics (ABS, PMMA, PC, PET, etc.) coated metals, UV-coated and

acid-resistant aluminum substrates.

Feature :Semi-gloss finish

Excellent rub resistance

Manufactured according to major corporate standards (CI no more than 700ppm,

Br no more than 700ppm,total halogen contents no more than 1100ppm)

Diluents : Standard solvent: T-640

Slow dry solvent : T-952

Mixing ratios: Mix in 10~15% D hardener.

Drying time : While air-drying is possible, curing at 80℃x30min is recommended to ensure optimal performance

Wash up : T-15/T-31

Notes : Adhesion and abrasion may vary due to substrate difference. Caution is advised.

Use CARE 39(no more than 10%) if adjustments to printability are required.

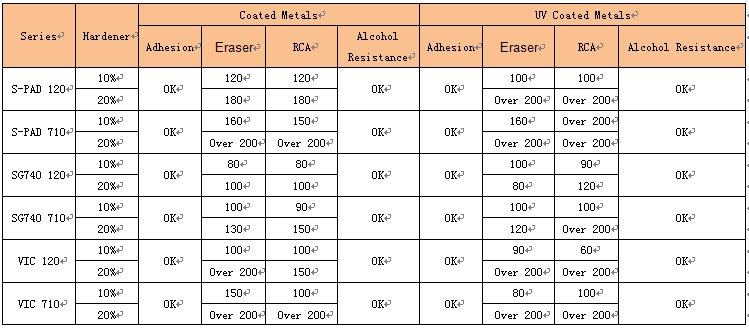

Reference Date

(Results below are from tests performed by Seiko Advance, and not to be taken as performance guarantee)

Note:

Adhesion : Nichiban tape test. Peeling test performance using specified tape after a cross-cut on printed surface,

no peeling was found

Alcohol test : printed surface was rubbed on 30 times with a cotton cloth soaked in 99% alcohol with a load of 500g.

No fading was found.

RCA paper tape test, Rubbed on printed surface with a load of 175 load.

Eraser test : Sony specialized eraser rubbed on printed surface with a loaded of 500g.

Printing method: Pad printing. |